CLEANING WITH MiniSWASH

- Single frame configuration

- Closed loop zero drain system

- Rotary direct spray

- Hot air knife direct dry technology

- Anti-collision system

- Compatible with chemistry from various suppliers

- Small footprint

- Clamping for all types of stencils and squeegees

- Adjustable frame fixing system

- Wide range of PCBA fixtures

- Two fully separated liquid loops

- Low consumption of chemicals and water

- Outstanding options of water utilization

- Intuitive touchscreen interface

- PLC control

- Barcode traceability, LAN connectivity

- Adaptive rinse process control

- Multi language selection

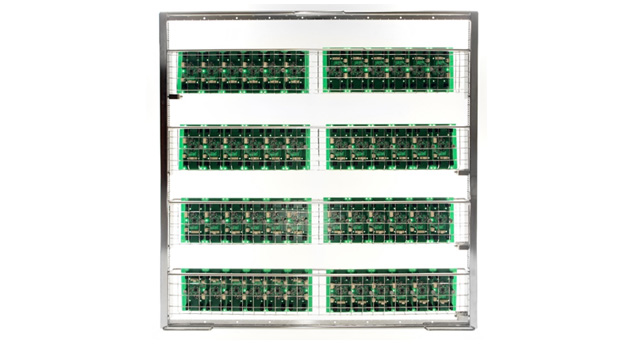

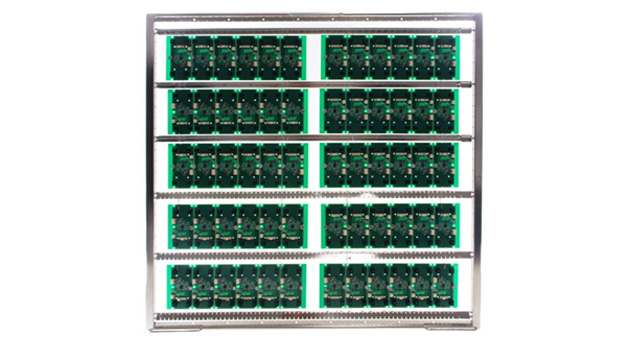

USABLE SPACE OF CHAMBER

Slider begining

FILTRATION

- Developed to match modern cleaning agents

- Wash loop is closed and fully filtrated process

- Filtration extends the bath life to lower the process costs

- Various efficient ways of processing contaminated rinse loop water

- Rinse loops are flexible by design to meet various process and environmental requirements

SEMI-OPEN FILTRATION

- Optional external water processing

- Easily connected to water supply and drain

- Only few litres of fresh water per cycle needed for stable rinse process

EXTERNAL CLOSED FILTRATION

- Stand-alone compact filtration unit can be connected to MiniSWASH at any time and transform into fully closed loop zero drain system

EXTERNAL CLOSED DOUBLE FILTRATION

- Intended for processes which require double rinse such as PCBA defluxing and fine misprint cleaning

WASH AND DRY

- Modern stencil cleaning chemistry is capable to clean without the necessity of additional rinse - so called self-rinsing chemicals

- Recommended for small capacity processes

Slider begining

CLAMPING

- Conventional framed stencils and screens fit directly into the built-in adjustable clamping

- Wide range of standard fixtures and adaptors for any type of stencils and PCBAs

- PBT Works can additionally custom design any special clamping fixture required

DEK VECTORGUARD HOLDER

- Slide-in adaptor for Dek VectorGuard stencil

- No need to take out the holder for quick changeover of stencils

BASKETS FOR MISPRINTS AND PCBA

- Stainless wire baskets for quick and easy loading of PCBAs

- Available in various sizes

- Quick exchange of basket types - no tool needed

HORIZONTAL BARS WITH SPRINGS

- According to IPC 610 PCBAs shall be handled by the edges which are generally technologically missing

- PBT Works developed special springs for fixing which can be positioned precisely along the horizontal bars to gain perfectly balanced grip force

- Spring bars allow to fix wide range of products from small and light to large and heavy, even unusually shaped

- Bars are quickly and easily adjustable in vertical direction with no need of tool

Slider begining

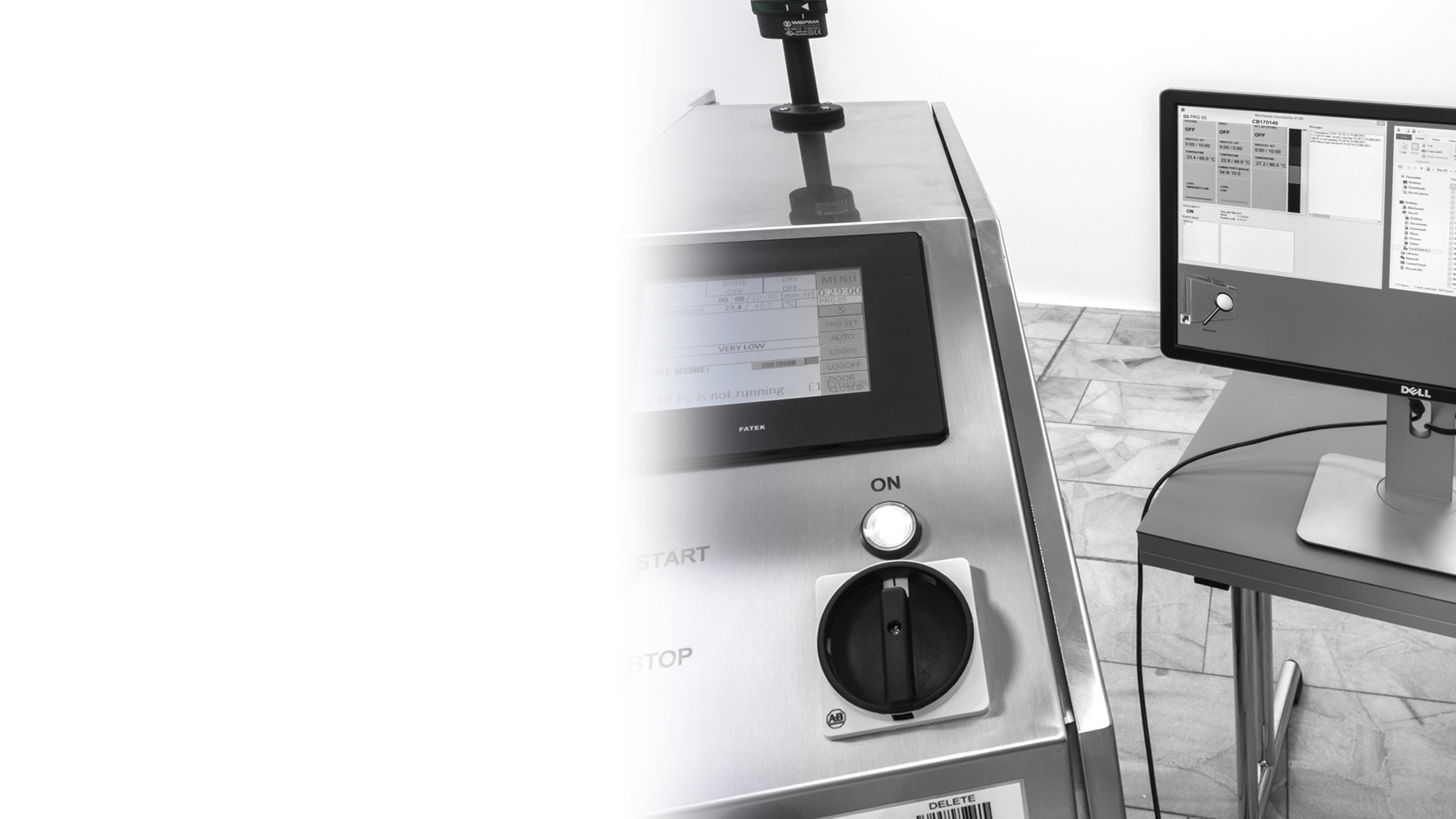

PROCESS CONTROL FEATURES

- Top quality cleaning requires powerful and perfectly stable process

- MiniSWASH software provides very detailed programming

- Full range of data monitoring to assure high repeatability of results

INTUITIVE TOUCHSCREEN INTERFACE

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistance)

- Indication of minimal level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- OS available in several different languages

BARCODE TRACEABILITY

- Optional barcode reader for product identification

- Automatic selection of the cleaning program through barcode

- Complete archiving of bar codes with process parameters

MiniSWASH Sales Downloads

MiniSWASH Service Downloads